Fragrance-Free and Dye-Free Industrial Degreasers

Once upon a time in industrial cleaning, a story was told about degreaser products. A brave technician battled with grease-covered metal parts while trying to remanufacture them. After a long, drawn-out day of scrubbing and scraping parts, the purchasing manager delivered a wonderful new weapon: a chemical that smelled like oranges!

The product worked because a chemist had found out some of the most effective degreasers were made with the oil of citrus peels: D-Limonene. This product was obtained through cold pressing the peels of various citrus fruits. While the product worked very well, it was (and still is) very costly to manufacture because of the volatility of citrus crops in South America. One bad freeze and the product can surge in price as the supply threatened. Over the years, two myths have originated about waging the war against grease.

Myth #1: Effective Degreasers Must Smell Like Citrus

Other chemical companies wanted to manufacture products that delivered cheaper methods of degreasing. They wanted to ensure the products smelled as fresh as the citrus based D-Limonene products. This move to disguise degreaser products led to the widespread use of citrus scents in many degreasers. But many consumers caught on to the ruse and started looking for cheaper and better products.

Myth #2: Good Degreasers Are Purple

This led to the second big myth that has been handed down from father to son and supervisor to technician in so many shops: If you want a good degreaser, it must be PURPLE! Color was the next area where people tried to differentiate their products from competitors. Once everything smelled like oranges, someone thought of adding dyes to the products. What’s the opposite of orange in the color palette? Purple.

Don’t Pay for Fragrance and Dyes

A Google Search on “purple degreasers” will return pages of purple liquids, labels, bottles, and barrels. While most people now associate oranges and purple with degreasers, you’re not guaranteed a product that actually performs better. So, why are you paying for the fragrance and dyes?

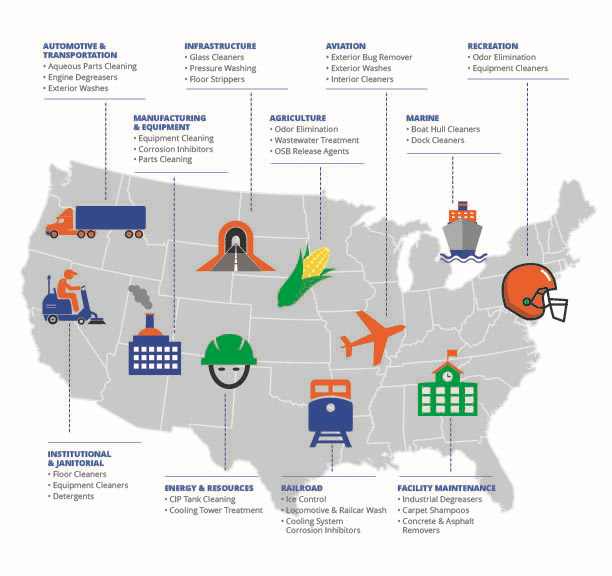

You shouldn’t. Seacole has a long history of manufacturing some of the most effective degreasers for several industries without fragrance or dyes. Our products look and smell like industrial cleaners because that is what they are. We have aqueous-based products for engine remanufacturing and transportation industries, a mild solvent that has applications from the removal of tar and asphalt on vehicles to the removal of tapes, adhesives, and vehicle wraps/decals, and degreasers specially formulated for food production plants, commercial ovens, and hoods and vents.

None of these products smell like oranges or are purple. They simply provide superior grease-fighting technology for your needs. Contact our industrial cleaning sales team to ask about our line-up of premium degreasers.

Water-Based Degreasers

Break

Break is a premium-quality, ready-to-use liquid spray formulated for general cleaning of all hard surfaces, including everything found in the office, factory, shop, vehicle, bathroom, and kitchen. Its grease-cutting formula is effective without scrubbing and removes greases, oils, inks, some aerosol paints, and some non-resistant enamel paints. It is safe for us on automotive paints, commercially applied equipment paints, and cured latex wall paints in normal use.

C&H 147

Our 147 degreaser is an economical liquid cleaner with butyl formulated for general cleaning of all hard surfaces. When mixed in a more concentrated form, 147 can power through the toughest of greases, oils, and fluids in engine and transmission remanufacturing shops. And like Break, it is capable of cleaning and degreasing everything found in the office, factory, shop, bathroom, and kitchen. Because of its super-concentrated form, 147 is our most versatile degreaser, allowing the customer to mix it as strong as they need for their specific application.

Mild Solvent Degreaser

956P

956P is a heavy-duty, environmentally safe coating remover for spray, brush, or soak applications in industrial maintenance shops. It removes transit coatings, cosmoline coatings, adhesives, tapes, and stenciling from hard surfaces, including steel, copper, brass, aluminum, plastics, rubber, and painted surfaces. 956P does not affect most paints or electrical insulations. It’s perfect for fleet managers who need to remove decals before trading in or sending.

Commercial Kitchen Degreasers

744

744 is a USDA-approved heavy-duty alkaline degreaser for use in commercial kitchens, food plants, and janitorial applications. It dissolves grease, soils, food, crayon, pencil marks, and scuff marks from steel, brass, countertops, floors, walls, and most other hard surfaces. It is effective in pressure washing applications on kitchen vent stacks and hoods.

748

748 is a heavy-duty, ready-to-use thickened liquid designed for cleaning commercial ovens and grills, including broilers, deep fat fryers, hoods, and greasy vents. This thickened product is designed to hang in place and can be applied by pouring or brushing the product on pre-heated surfaces. It is not recommended for use on aluminum or other sensitive materials.

Seacole Product Tags:

It’s sunny, warm, and your chore list is already fairly long. Why not put off the maintenance on your heavy farm equipment? Unfortunately, ignoring routine maintenance and care of your heavy equipment—especially those hard-to-clean places—can lead to a much bigger problem down the road.

It’s sunny, warm, and your chore list is already fairly long. Why not put off the maintenance on your heavy farm equipment? Unfortunately, ignoring routine maintenance and care of your heavy equipment—especially those hard-to-clean places—can lead to a much bigger problem down the road.

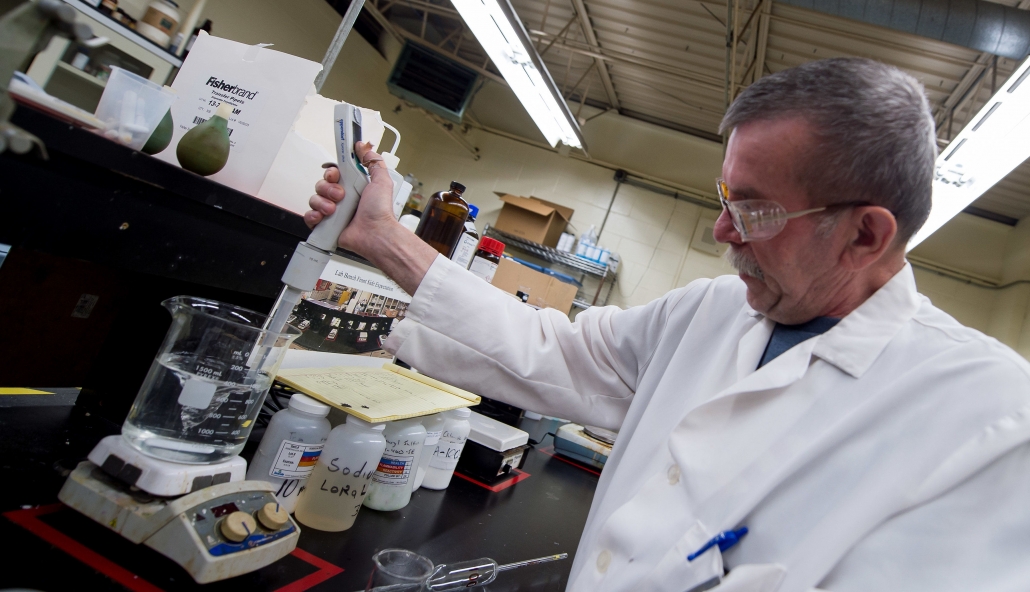

We had a chance this month to catch up with printed circuit board account manager Walt Forgacs. Walt’s been a chemist and engineer for more than three decades, and we’re grateful for the addition his expertise and experience make to the Seacole team. Take a moment to get to know Walt!

We had a chance this month to catch up with printed circuit board account manager Walt Forgacs. Walt’s been a chemist and engineer for more than three decades, and we’re grateful for the addition his expertise and experience make to the Seacole team. Take a moment to get to know Walt!

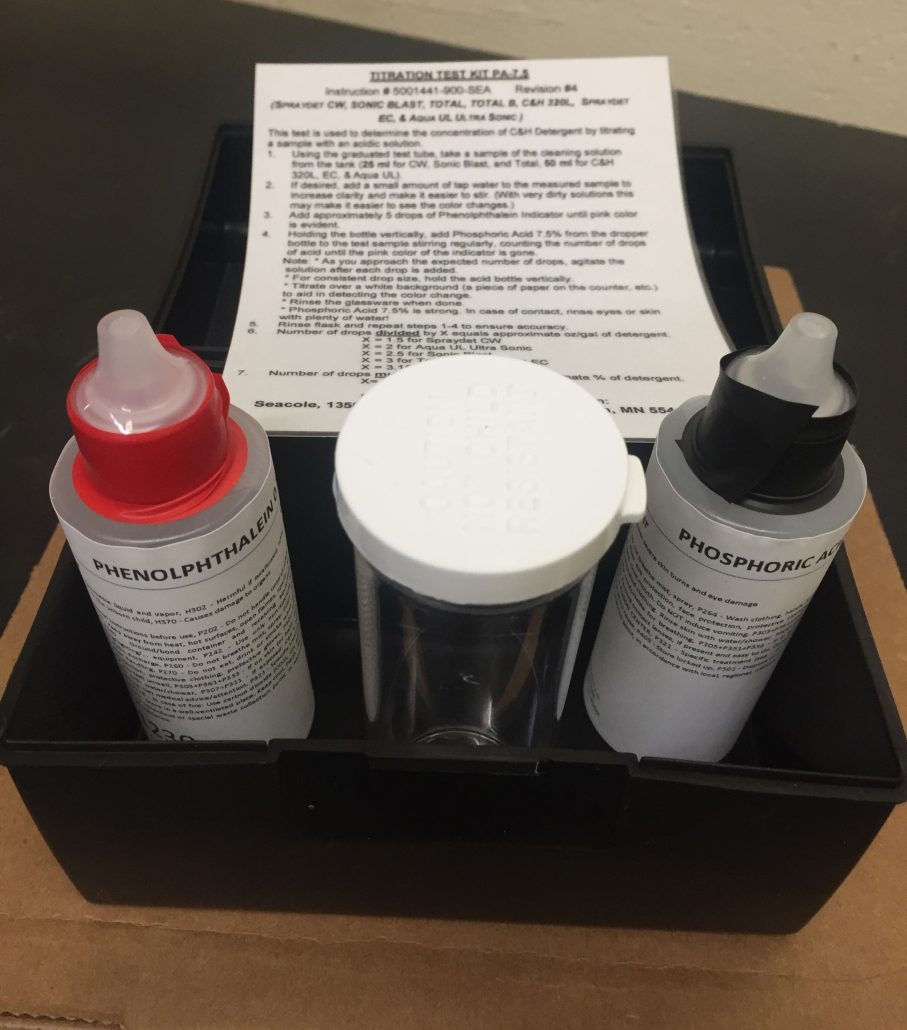

We had a chance this month to catch up with surface finishing account manager Jim Jordan. Jim holds a chemical engineering degree from the University of Minnesota Twin Cities and enjoys helping customers improve their process control methods. Take a moment to get to know Jim!

We had a chance this month to catch up with surface finishing account manager Jim Jordan. Jim holds a chemical engineering degree from the University of Minnesota Twin Cities and enjoys helping customers improve their process control methods. Take a moment to get to know Jim!

Parts cleaners, corrosion inhibitors, defoamers, degreasers, detergents, and descalers—Seacole Specialty Chemical can formulate an industrial cleaner for your industrial process. Our custom liquid blending capabilities help you eliminate contaminants without damaging your products. Here are seven different applications for our custom-blended industrial cleaners. Which one might be just what your industrial process needs?

Parts cleaners, corrosion inhibitors, defoamers, degreasers, detergents, and descalers—Seacole Specialty Chemical can formulate an industrial cleaner for your industrial process. Our custom liquid blending capabilities help you eliminate contaminants without damaging your products. Here are seven different applications for our custom-blended industrial cleaners. Which one might be just what your industrial process needs?

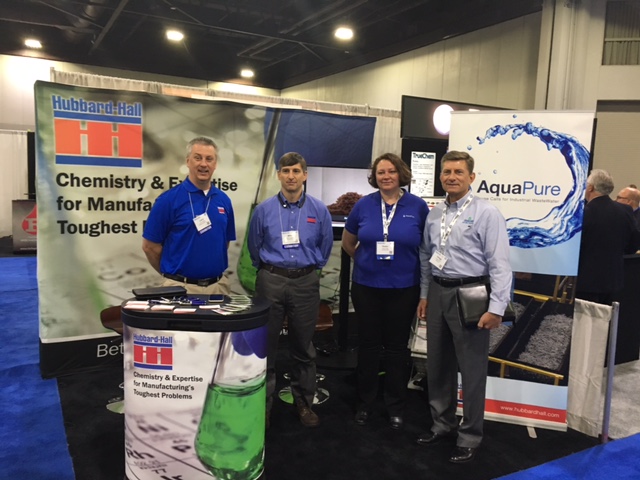

Seacole is a proud member of the National Association of Chemical Distributors (NACD). As a supplier of specialty chemicals, we’re your connection to the nation’s top chemical distributors. We take our position in the supply chain very seriously, from the health and safety of your employees and ours to the safe transportation, use, and disposal of the products we offer.

Seacole is a proud member of the National Association of Chemical Distributors (NACD). As a supplier of specialty chemicals, we’re your connection to the nation’s top chemical distributors. We take our position in the supply chain very seriously, from the health and safety of your employees and ours to the safe transportation, use, and disposal of the products we offer.

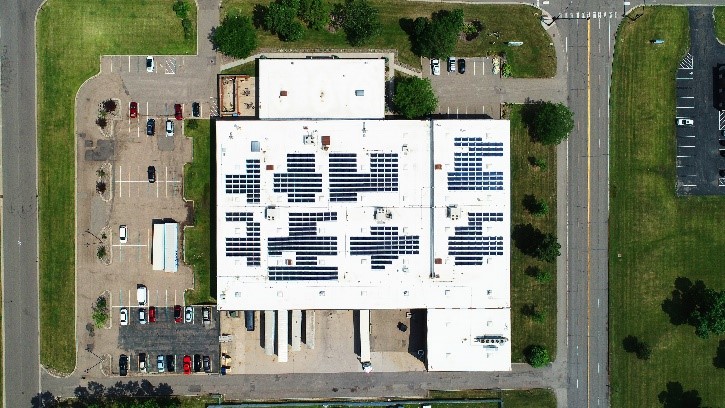

For 15 years, Seacole Specialty Chemical has been your resource for highly specialized chemical products that support every stage of your manufacturing process. We

For 15 years, Seacole Specialty Chemical has been your resource for highly specialized chemical products that support every stage of your manufacturing process. We